CNC online instant quote systems have revolutionized the way businesses and engineers procure precision-machined parts. By leveraging advanced algorithms, artificial intelligence (AI), and machine learning, these platforms provide real-time pricing and manufacturability feedback, streamlining the CNC machining process. This comprehensive guide explores the advantages and disadvantages of CNC online instant quote systems, highlights leading platforms, and provides detailed insights into their functionality, technical parameters, and applications across industries like aerospace, automotive, and medical. Whether you're a designer seeking rapid prototyping or a manufacturer managing high-volume production, understanding these systems can optimize your workflow and decision-making.

What is a CNC Online Instant Quote System?

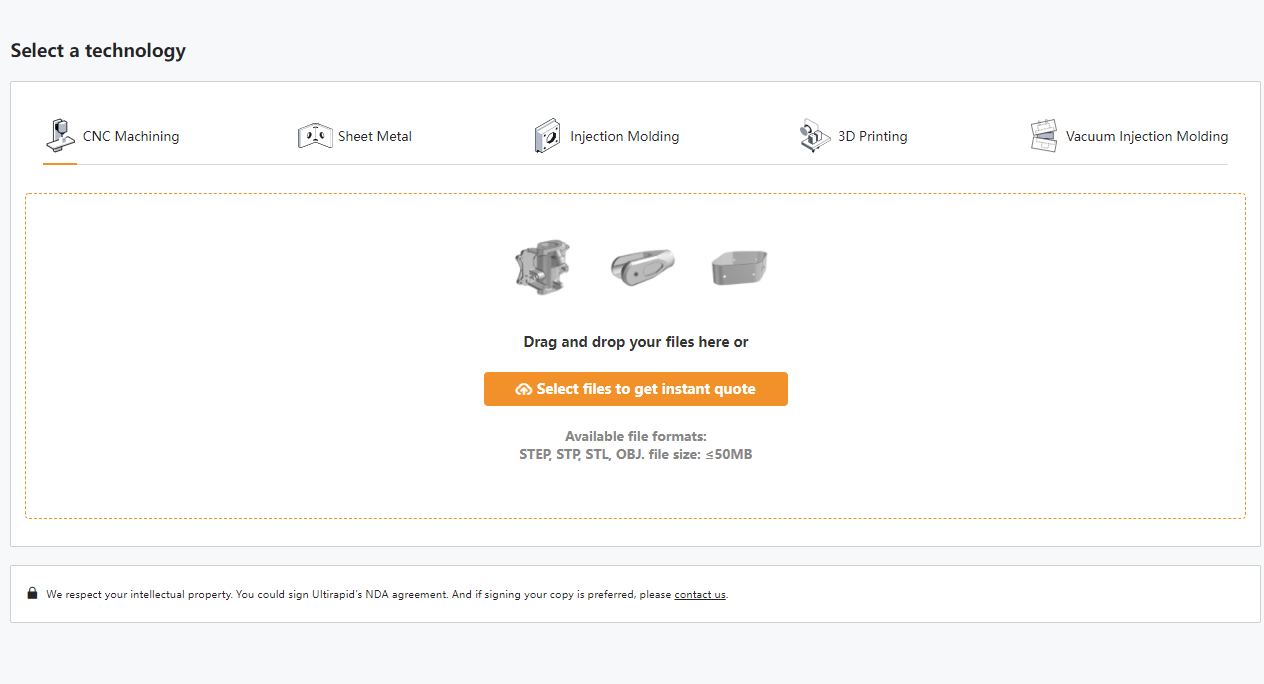

A CNC online instant quote system is a digital platform that allows users to upload CAD (Computer-Aided Design) files and receive immediate pricing, lead times, and design-for-manufacturability (DFM) feedback for CNC machining projects. These systems use sophisticated algorithms to analyze part geometry, material requirements, tolerances, and surface finishes, generating accurate quotes in seconds or minutes. Unlike traditional quoting processes, which can take days and involve manual calculations, instant quote systems automate the process, enhancing efficiency and accessibility for prototyping, low-volume production, and high-volume manufacturing.

How CNC Instant Quote Systems Work

The operation of a CNC online instant quote system involves several key steps, each designed to provide fast and accurate results. Here’s an overview of the process:

- File Upload: Users upload CAD files in formats like STEP, IGES, or SLDPRT. The system supports 3D models with tolerances as tight as ±0.005 mm.

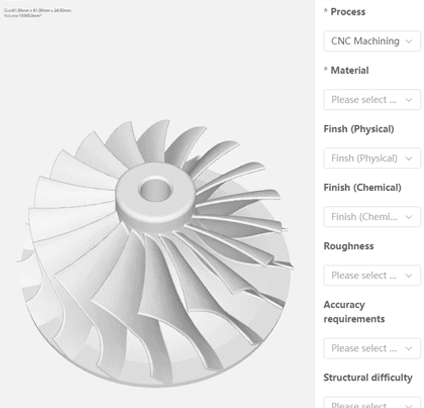

- Geometry Analysis: Algorithms analyze part dimensions, surface area, volume, and features (e.g., holes, slots, threads) to estimate machining time and complexity.

- Material Selection: Users choose from materials like aluminium (6061, 7075), stainless steel (304, 316), or plastics (PEEK, POM), with material densities ranging from 1.2 g/cm³ (plastics) to 8.0 g/cm³ (steel).

- Finish and Tolerance Specification: Options include as-machined (Ra 0.8–1.6 µm), anodizing (Type II, 5–25 µm), or powder coating (50–150 µm).

- Quote Generation: The system calculates costs based on machining time (e.g., 20–300 seconds/feature), material costs, and labor rates, delivering quotes in 5–60 seconds.

- DFM Feedback: Automated analysis identifies potential manufacturability issues, such as thin walls (0.5 mm) or complex geometries requiring 5-axis machining.

Technical Parameters of Instant Quote Systems

CNC instant quote systems rely on precise parameters to ensure accuracy and reliability. Key parameters include:

- File Formats: Supports STEP (AP203, AP214), IGES, SLDPRT, and X_T, with file sizes up to 100 MB.

- Tolerance Range: Quotes parts with tolerances from ±0.005 mm to ±0.1 mm, suitable for aerospace and medical applications.

- Material Options: Over 40 materials, including metals (tensile strength 200–1,300 MPa) and plastics (melting points 150–343°C).

- Surface Finish Options: Ranges from Ra 0.2 µm (polished) to Ra 3.2 µm (as-machined).

- Machining Capabilities: Supports 3-, 4-, and 5-axis milling and turning, with maximum part sizes up to 2 meters.

- Quote Accuracy: Algorithms achieve ±5% accuracy for pricing, with machine learning improving precision over time.

Advantages of CNC Online Instant Quote Systems

CNC online instant quote systems offer numerous benefits that transform the traditional procurement process for machined parts. Below are the key advantages, supported by industry insights and technical details.

Time Efficiency

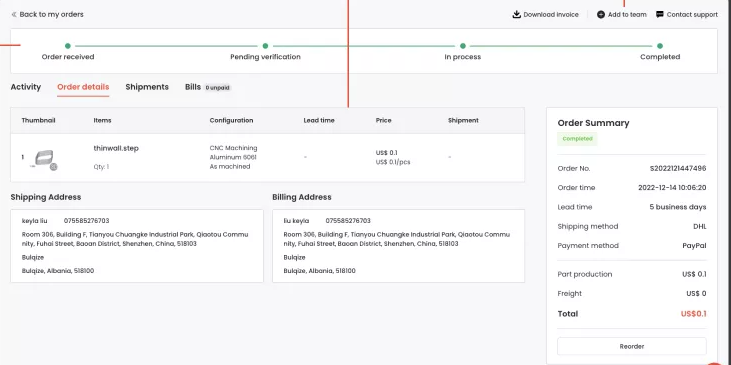

Instant quote systems eliminate the lengthy manual quoting process, which can take 1–5 days in traditional setups. By providing quotes in 5–60 seconds, these platforms accelerate project timelines, enabling rapid prototyping and faster market entry. For example, platforms like MakerVerse and AMFG report reducing quoting times by up to 90%, allowing engineers to focus on design and innovation.

Cost Transparency and Savings

These systems provide real-time pricing, enabling users to compare costs across materials, tolerances, and finishes instantly. By optimizing designs during the quoting process (e.g., avoiding thin walls or complex features), users can reduce costs by 10–20%. Platforms like InstaWerk leverage large manufacturing networks to secure competitive pricing, passing savings to customers through economies of scale.

Enhanced Accessibility

Instant quote systems are accessible 24/7, allowing global users to upload files and receive quotes at any time. This is particularly beneficial for small and medium enterprises (SMEs) without in-house manufacturing capabilities, as they can access a network of over 1,000 CNC machines through platforms like Xometry or Unionfab.

Automated DFM Feedback

Advanced platforms provide real-time DFM analysis, identifying manufacturability issues such as unsupported geometries or excessive tolerances. For instance, Plethora’s Auto DFM system delivers feedback within seconds, reducing design iterations and preventing costly errors. This feature is critical for complex parts requiring 5-axis machining.

Quality Assurance Through Network Specialization

Many platforms, such as InstaWerk, operate closed manufacturing networks where suppliers are vetted for quality. Orders are matched to manufacturers based on expertise, ensuring high-precision parts with tolerances as tight as ±0.005 mm. Continuous quality audits and performance metrics reward top suppliers with more orders, enhancing reliability.

Disadvantages of CNC Online Instant Quote Systems

While CNC instant quote systems offer significant benefits, they also have limitations that users must consider. Below are the key disadvantages, grounded in industry perspectives.

Limited Accuracy for Complex Parts

Instant quote systems may struggle with highly complex parts requiring custom tooling or non-standard processes. Algorithms rely on historical data and simplified assumptions (e.g., bounding box, surface area), which can lead to pricing errors of ±10–15% for intricate geometries. Manual review is often needed for such projects, reducing the “instant” benefit.

Dependence on CAD File Quality

The accuracy of quotes depends heavily on the quality of uploaded CAD files. Incomplete or poorly formatted files (e.g., missing tolerances or incorrect formats) can result in inaccurate pricing or DFM feedback. Platforms like Renovo CNC recommend using STEP AP203/AP214 files to ensure precision, but this requires user expertise.

Potential for Lower Quality in Low-Cost Shops

Some platforms prioritize cost over quality, contracting lower-cost shops that may deliver subpar parts. As noted in industry discussions, shops supplying platforms like Xometry may face low pay, leading to high turnover and inconsistent quality. Users must verify supplier certifications (e.g., ISO 9001:2015) to ensure reliability.

Limited Customization for Non-Standard Requirements

Instant quote systems are optimized for standard part sizes, materials, and tolerances. Non-standard requirements, such as ultra-tight tolerances (±0.001 mm) or exotic materials like tungsten carbide, often require manual quoting, negating the speed advantage.

Data Security Concerns

Uploading proprietary CAD files to online platforms raises concerns about data security. While platforms like Weerg and InstaWerk use ISO 27001-certified servers, users must ensure confidentiality through non-disclosure agreements (NDAs) or secure file handling.

Why Choose Kesu’s CNC Quote?

Personalized Service and Client Collaboration

Kesu’s manual quoting system prioritizes direct communication with clients, ensuring that every project detail is thoroughly understood. After receiving CAD files (e.g., STEP, IGES, or SLDPRT), Kesu’s engineers engage with clients to clarify specifications, such as material properties (e.g., aluminium 6061 with tensile strength 310 MPa) or surface finishes (Ra 0.4 µm). This collaboration reduces misunderstandings and ensures quotes reflect the exact project scope, fostering trust and long-term partnerships.

Expert-Driven Accuracy for Complex Projects

Manual quoting allows Kesu’s experienced engineers to assess complex geometries and non-standard requirements that automated systems may misinterpret. For example, parts requiring 5-axis CNC machining (with rotational angles up to ±120°) or exotic materials like Inconel 625 (tensile strength 1,300 MPa) benefit from human analysis. This expertise minimizes pricing errors, which can exceed ±10% in instant quote systems for intricate parts, ensuring cost accuracy and project feasibility.

Flexibility for Non-Standard Requirements

Kesu’s CNC Quote excels in handling non-standard projects, such as large-scale parts (up to 2 meters) or custom tolerances (±0.005 mm). Unlike instant quote platforms, which are optimized for standard sizes and materials, Kesu’s team can accommodate unique specifications, including special alloys or hybrid manufacturing processes (e.g., CNC machining combined with metal 3D printing). This flexibility is critical for bespoke applications in industries like intelligent automation and embossing rollers.

Leading CNC Online Instant Quote Platforms

Several platforms have emerged as leaders in CNC online instant quoting, each offering unique features and capabilities. Below is an overview of the top platforms, including their technical specifications and target applications.

Xometry

Xometry is a global leader with a network of over 10,000 suppliers, offering instant quotes for CNC milling, turning, and other processes. Key features include:

- Materials: Over 40 materials, including aluminium 6061 (tensile strength 310 MPa) and PEEK (melting point 343°C).

- Tolerances: Supports ±0.005 mm for metals and ±0.01 mm for plastics.

- Lead Times: As fast as 1 day for prototypes.

- Certifications: ISO 9001:2015, AS9100D, ITAR-registered.

- Applications: Aerospace, medical, robotics, electronics.

Xometry’s Instant Quoting Engine provides DFM feedback and supports high-volume production, making it ideal for complex projects.

Protolabs

Protolabs is renowned for its speed, delivering parts in as little as 1 day. Its instant quote system supports CNC milling and turning with a focus on prototyping.

- Materials: Includes aluminium 7075 (tensile strength 570 MPa), stainless steel 316 (yield strength 205 MPa), and Delrin (stiffness 2.8 GPa).

- Tolerances: Achieves ±0.01 mm for most geometries.

- Finishes: As-machined (Ra 0.8 µm), anodizing, and powder coating.

- Applications: Medical devices, automotive, consumer electronics.

Protolabs’ real-time pricing and DFM analysis make it a top choice for rapid prototyping.

InstaWerk

InstaWerk, based in Germany, operates a closed manufacturing network for high-quality CNC parts. Its instant quote system emphasizes precision and cost-effectiveness.

- Materials: Supports metals like titanium (Grade 5, yield strength 880 MPa) and plastics like POM (density 1.41 g/cm³).

- Tolerances: Down to ±0.004 mm.

- Lead Times: From 5 business days.

- Certifications: ISO 9001:2015, ISO 27001.

- Applications: Automotive, machinery, industrial equipment.

InstaWerk’s intelligent order matching ensures parts are assigned to specialized manufacturers, enhancing quality.

MakerVerse

MakerVerse uses AI-powered quoting to support 3- and 5-axis CNC machining, offering over 150 materials and 75 surface finishes.

- Materials: Includes Inconel 625 (tensile strength 1,300 MPa) and HDPE (density 0.95 g/cm³).

- Tolerances: Supports ±0.01 mm for complex parts.

- Lead Times: As fast as 3 days.

- Certifications: ISO 9001:2015, AS9100D.

- Applications: Aerospace, robotics, machinery.

MakerVerse’s platform excels at handling intricate parts and provides comprehensive customization options.

Weerg

Weerg, based in Italy, offers a true in-house CNC machining service with instant quotes and 3-day delivery.

- Materials: Aluminium, steel, brass, and plastics like PMMA (tensile strength 70 MPa).

- Tolerances: Achieves ±0.01 mm.

- Finishes: Bluing, zincing, anodizing (Ra 0.4–3.2 µm).

- Certifications: ISO 9001:2015, EN-10204:2004.

- Applications: Aerospace, automotive, cultural industries.

Weerg’s in-house production ensures confidentiality and consistent quality, ideal for EU-based clients.

Why Use CNC Online Instant Quote Systems?

CNC online instant quote systems are a game-changer for engineers, designers, and manufacturers. They offer:

- Speed: Quotes in seconds versus days.

- Cost Efficiency: Transparency and DFM feedback reduce costs by 10–20%.

- Quality: Vetted supplier networks ensure tolerances as tight as ±0.005 mm.

- Flexibility: Support for prototyping, low-volume, and high-volume production.

By choosing a reputable platform, businesses can streamline procurement, enhance design efficiency, and maintain competitive pricing.

Frequently Asked Questions (FAQ)

What is a CNC online instant quote system?

A CNC online instant quote system is a digital platform that provides immediate pricing, lead times, and DFM feedback for CNC machining projects by analyzing uploaded CAD files.

What are the advantages of instant quote systems?

Advantages include time efficiency (quotes in seconds), cost transparency, automated DFM feedback, accessibility, and quality assurance through specialized supplier networks.

What are the disadvantages of instant quote systems?

Disadvantages include limited accuracy for complex parts, dependence on CAD file quality, potential quality issues with low-cost shops, limited customization, and data security concerns. You can Kesu’s online CNC quote instead.

Which platforms offer online CNC quote system?

Leading platforms include Xometry, Protolabs, InstaWerk, MakerVerse, and Weerg, each offering unique features like AI-driven quoting, 5-axis machining, and rapid delivery.

How accurate are instant quotes?

Instant quotes typically achieve ±5% accuracy for pricing, with machine learning improving precision over time, though complex parts may require manual review.