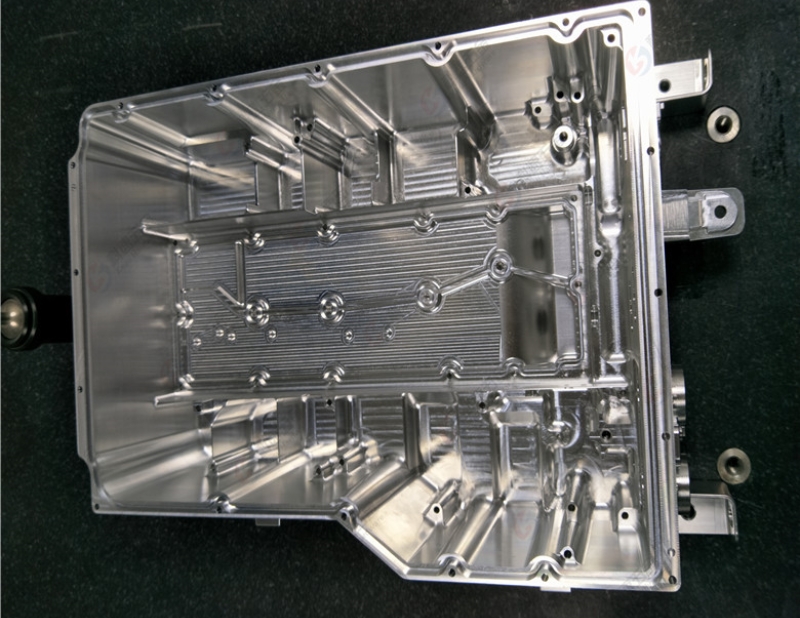

Kesu Hardware Group, based in Dongguan, China, is a premier machined components manufacturer renowned for delivering high-precision machined parts with exceptional quality and rapid turnaround times. Our state-of-the-art CNC machining capabilities, coupled with a commitment to excellence, make us a trusted partner for industries worldwide. Whether you need custom components for aerospace, automotive, medical, or other sectors, we provide tailored solutions with no minimum order quantity (MOQ).

Precision is at the heart of what we do. Our advanced CNC machines and skilled engineers ensure that every part meets stringent tolerances and specifications. From complex geometries to specialized materials, we handle it all with expertise and efficiency.

Why Choose Kesu Hardware for Precision Machined Components?

Manufacturing high-precision machined components requires a blend of advanced technology, skilled craftsmanship, and rigorous quality control. At Kesu Hardware, we excel in all these areas, setting us apart from other machined components manufacturers. Here’s why our clients trust us:

- Advanced CNC Technology: Our facility is equipped with 5-axis machining centers, CNC lathes, and multi-tasking turning centers for unparalleled precision.

- Material Expertise: We work with a wide range of materials, including Stainless Steel, Aluminum, Titanium, PEEK, and more, ensuring optimal performance for your parts.

- Fast Turnaround: Our streamlined processes and dedicated team enable us to deliver parts quickly without compromising quality.

- Comprehensive Services: From CNC machining to surface treatments and heat treatments, we offer one-stop solutions.

- No MOQ: Whether you need a single prototype or a small batch, we cater to all order sizes.

Our Commitment to Quality

Quality is non-negotiable at Kesu Hardware. We adhere to international standards such as ISO 2768-F for metal parts and ISO 2768-M for plastics. Our inspection equipment, including Coordinate Measuring Machines (CMM) and XRF Spectrometers, ensures every component meets your exact specifications. Our tolerances are among the tightest in the industry, with capabilities as low as ±0.002 mm for metal parts.

Industries We Serve

Our precision machined components are integral to a variety of industries, including:

- Aerospace: High-strength, lightweight components for aircraft and spacecraft.

- Automotive: Durable parts for engines, transmissions, and chassis.

- Medical and Dental: Biocompatible components for surgical tools and implants.

- Electronics: Precision parts for instrumentation and consumer devices.

- Hydraulic Equipment: Robust components for fluid power systems.

- Textiles: Specialized parts for manufacturing equipment.

Our CNC Machining Capabilities

At Kesu Hardware, we leverage cutting-edge CNC technology to produce complex, high-precision machined components. Our facility in Dongguan is equipped with a diverse range of machines, enabling us to handle projects of varying complexity and volume.

CNC Equipment Overview

| Equipment Type | Quantity | Brand | Max Part Size |

|---|---|---|---|

| 5-Axis Machining Centers | 10 | Jingdiao/DMG Mori | D600 mm |

| CNC Lathes | 50 | Tsugami | D300 x L1200 mm |

| Live Tool CNC Turning Centers | 10 | Tsugami | D300 x L1200 mm |

| Horizontal Machining Centers | 20 | AutoCam | D600 x L1200 mm |

| Vertical Machining Centers | 20 | AutoCam | 1500 x 800 mm |

| Tool Grinders | 5 | - | - |

| Multi-Tasking Turning Centers | 10 | Mazak/DMG Mori | D300 x L1200 mm |

Specialized CNC Processes

Our advanced equipment enables us to perform specialized machining processes, including:

- Deburring: Removing sharp edges for safety and functionality.

- Honing: Achieving ultra-smooth surfaces for precision fits.

- Hard Turning: Machining hardened materials with high accuracy.

- OD Grinding: Ensuring precise outer diameters for cylindrical parts.

Tolerance Capabilities

| Feature | Tolerance (Metal, mm) | Tolerance (Plastic, mm) |

|---|---|---|

| Linear Dimensions | ±0.01 | ±0.05 |

| Diameter | ±0.002 | ±0.02 |

| Precise Hole | ±0.002 | ±0.02 |

| Straightness | ±0.002 | ±0.02 |

| Flatness | ±0.002 | ±0.01 |

| Concentricity | ±0.002 | ±0.005 |

Materials for Precision Machined Components

The performance of a machined component is heavily influenced by its material. At Kesu Hardware, we have extensive experience working with a broad spectrum of materials, each chosen for its unique properties to meet the demands of specific applications.

Metals

We specialize in machining a variety of metals, ensuring durability, strength, and precision:

- Stainless Steel:

- Austenitic: 303, 304, 316 (corrosion-resistant, ideal for medical and marine applications).

- Precipitation Hardening: 17-4 PH, 15-5 (high strength and toughness).

- Other Variants: 440C, 420, 410 (wear-resistant, used in tooling).

- Tool Steel: CVM-350, CPMV series, D2, A2, S7, O1, W1 (high hardness, used for cutting tools and dies).

- Aluminum Alloys: 5052, 6061-T6, 7075-T6 (lightweight, excellent strength-to-weight ratio).

- Alloy Steel:

- Low-Carbon: 16Mn, 4118, 16MnCr5, 8620 (good machinability).

- Medium-Carbon: 4340, 4140 (high strength for structural components).

- Nitrided: 34CrAlMo5V, 31CrMoV9 (wear-resistant).

- Brass: CDA 360/385 (corrosion-resistant, used in fittings and connectors).

- Nickel: CDA 798 NM2, CDA 793 N12 (high corrosion resistance).

- Other Metals: Titanium (lightweight, biocompatible), Beryllium Copper (high conductivity), Tellurium Copper (easy to machine).

Plastics and Other Materials

We also machine high-performance plastics and specialty materials for applications requiring unique properties:

- Delrin: High stiffness, low friction, ideal for gears and bearings.

- PEEK: Excellent chemical resistance, used in medical and aerospace.

- Nylon: Tough and wear-resistant, suitable for bushings.

- PTFE: Low friction, high heat resistance.

- PC (Polycarbonate): Impact-resistant, used in electronics.

- PMMA (Acrylic): Transparent, used for optical components.

- Ceramics: High hardness, used in wear-resistant applications.

Surface Treatments and Finishes

To enhance the performance, durability, and aesthetics of our machined components, we offer a range of surface treatments and finishes:

- Anodizing: Improves corrosion resistance and aesthetics for Aluminum parts.

- Hard Anodizing: Increases wear resistance for demanding applications.

- Electroplating: Zinc, Nickel, or Chrome plating for corrosion protection.

- Powder Coating: Durable, protective finish in various colors.

- Passivation: Enhances corrosion resistance for Stainless Steel.

- Polishing: Achieves mirror-like surfaces for aesthetic or functional purposes.

- Sandblasting: Creates uniform surface textures.

- Laser Marking: Permanent, precise labeling for traceability.

Quality Assurance and Inspection

Our commitment to quality is backed by rigorous inspection processes and advanced equipment. We ensure every component meets your specifications through:

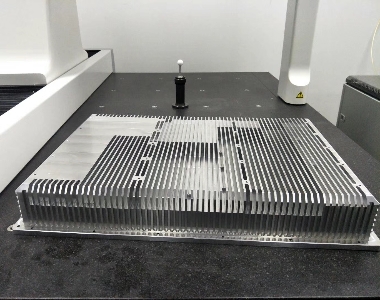

- Coordinate Measuring Machines (CMM): 2 units (LEAD brand) for precise dimensional checks.

- XRF Spectrometer: 1 unit (HITACHI) for material composition analysis.

- 2.5D Measuring Systems: 3 units for detailed surface inspections.

- Calipers and Micrometers: 20 calipers and 10 micrometers for manual checks.

We adhere to ISO 2768 standards, ensuring tolerances as tight as ±0.002 mm for metal parts and ±0.01 mm for plastics. Our quality control team conducts thorough inspections at every stage of production.

Why Kesu Hardware Stands Out

As a leading machined components manufacturer, Kesu Hardware combines technical expertise, advanced technology, and customer-centric service to deliver exceptional results. Here’s what sets us apart:

- Experienced Team: Over 30 engineers and 200 employees dedicated to precision manufacturing.

- Large Facility: 8,000+ square meters of manufacturing space.

- Global Reach: Serving 3,000+ customers worldwide with 500,000+ parts produced annually.

- Customer Support: Certified experts provide prompt, personalized service.

Our ability to handle complex projects, from prototyping to low-volume production, makes us a preferred partner for industries requiring high-precision components.

How to Work with Kesu Hardware

Getting started with Kesu Hardware is simple. Follow these steps to bring your project to life:

- Submit Your Design: Upload 2D and 3D drawings with material, finish, and quantity details.

- Receive a Quote: Get an instant quote via our website or by emailing.

- Production: Our team begins machining your parts with precision and efficiency.

- Quality Inspection: Every part undergoes rigorous checks to ensure compliance.

- Delivery: Your components are shipped promptly to your location.

FAQ: Machined Components Manufacturing

What are precision machined components?

Precision machined components are parts manufactured using CNC machines to achieve tight tolerances and complex geometries. They are used in industries like aerospace, automotive, and medical for high-performance applications.

What materials can Kesu Hardware machine?

We machine a wide range of materials, including Stainless Steel (303, 304, 316), Aluminum (6061, 7075), Titanium, PEEK, Delrin, and more. Contact us for specific material requirements.

What tolerances can you achieve?

We achieve tolerances as tight as ±0.005 mm for metal parts (e.g., diameters, holes) and ±0.01 mm for plastics (e.g., flatness, parallelism).

What industries do you serve?

We serve industries such as aerospace, automotive, medical, electronics, hydraulics, and textiles, providing custom components tailored to each sector’s needs.

How can I request a quote?

Upload your 2D and 3D drawings with material, finish, and quantity details on our website or email us for an instant quote.