This document provides a comprehensive overview of NVIDIA graphics cards, focusing on their classification and the precision manufacturing technologies employed in their production. NVIDIA, a leading designer of graphics processing units (GPUs), categorizes its products into distinct series tailored for specific applications, such as gaming, professional visualization, data center computing, and embedded systems. Each category demands unique manufacturing techniques to achieve high performance, reliability, and efficiency.

Prototype development is an indispensable part of NVIDIA's graphics card development lifecycle. It enables the company to mitigate risks, optimize performance, and ensure that each series of graphics cards meets the unique demands of its target application, laying a solid foundation for the precision manufacturing that follows.

Classification of NVIDIA Graphics Cards

NVIDIA graphics cards are segmented into several product lines, each designed to meet specific user requirements. The primary classifications include GeForce, Quadro, A100/H100, and Tegra series. These categories differ in their target applications, architectural design, and performance specifications, influencing the manufacturing technologies used.

GeForce Series

The GeForce series is NVIDIA’s flagship line for gaming and consumer applications. Models like the GeForce RTX 4090 and RTX 5090 are built for high-performance gaming, supporting advanced features such as real-time ray tracing, DLSS (Deep Learning Super Sampling), and AI-enhanced rendering. These GPUs are based on architectures like Ada Lovelace or Blackwell, featuring thousands of CUDA cores, high memory bandwidth, and GDDR6X memory.

Key specifications of the GeForce RTX 4090 include:

- CUDA Cores: 16,384

- Boost Clock: 2.52 GHz

- Memory: 24 GB GDDR6X, 384-bit memory bus

- RT Cores: 128 (3rd generation)

- Tensor Cores: 512 (4th generation)

- TDP: 450W

GeForce cards are designed for retail and add-in-board (AIB) partners like ASUS, MSI, and Gigabyte, who assemble the final products with custom cooling and power delivery systems.

Quadro Series

The Quadro series targets professional visualization, catering to industries such as architecture, engineering, and media production. Quadro GPUs, such as the RTX 6000 Ada, prioritize precision, stability, and support for professional software like Autodesk Maya and Adobe Premiere Pro. They feature large memory capacities and enhanced error-correcting code (ECC) memory for reliable computation.

Key specifications of the Quadro RTX 6000 Ada include:

- CUDA Cores: 18,176

- Memory: 48 GB GDDR6 with ECC

- Memory Bandwidth: 960 GB/s

- NVLink Support: Enables multi-GPU configurations

Quadro cards are optimized for workstation environments, requiring robust thermal management and high-quality components to ensure long-term reliability.

A100/H100 Series

The A100 and H100 GPUs are designed for data centers, focusing on artificial intelligence (AI), high-performance computing (HPC), and machine learning. Built on the Ampere (A100) and Hopper (H100) architectures, these GPUs leverage Tensor Cores for matrix operations and support high-bandwidth memory (HBM3) for massive data throughput.

Key specifications of the H100 include:

- Tensor Cores: 528 (4th generation)

- Memory: 141 GB HBM3

- Memory Bandwidth: 3 TB/s

- FP8 Precision: 4 petaFLOPS

These GPUs are used in supercomputers and cloud computing platforms, demanding extreme precision in manufacturing to handle high thermal and power loads.

Tegra Series

The Tegra series consists of system-on-chip (SoC) units for mobile and embedded applications, such as automotive systems (NVIDIA Drive) and portable gaming devices. Tegra chips integrate CPU, GPU, and memory controllers on a single die, prioritizing power efficiency and compact design.

Key specifications of the Tegra Orin include:

- GPU Cores: 2,048 CUDA cores

- CPU: 12-core Arm Cortex-A78AE

- Power Consumption: 15-60W

Tegra chips are critical for autonomous vehicles and IoT devices, requiring specialized manufacturing for integration and low power consumption.

Precision Manufacturing Technologies for NVIDIA GPUs

The production of NVIDIA graphics cards involves advanced semiconductor manufacturing and assembly processes. These technologies ensure high performance, energy efficiency, and reliability across different GPU classes. The primary manufacturing partner for NVIDIA’s GPU dies is Taiwan Semiconductor Manufacturing Company (TSMC), with additional assembly by AIB partners. Below, we detail the key precision manufacturing technologies involved.

Semiconductor Fabrication Processes

NVIDIA GPUs are manufactured using cutting-edge process nodes, which determine the size and efficiency of transistors. Smaller nodes allow for higher transistor density, improving performance and power efficiency. TSMC’s process nodes used for NVIDIA GPUs include:

| Process Node | GPU Examples | Transistor Size | Key Features |

|---|---|---|---|

| 4nm (N4) | GeForce RTX 4090, H100 | ~4 nm | High transistor density, low power consumption |

| 5nm (N5) | RTX 30 Series, A100 | ~5 nm | Improved performance over 7nm |

| 7nm (N7) | Turing GPUs (RTX 20 Series) | ~7 nm | Balanced power and performance |

The 4nm process, used in the latest GPUs, employs extreme ultraviolet (EUV) lithography with approximately 15 EUV layers and 80 deep ultraviolet (DUV) layers. Each layer requires nanometer-level alignment precision, achieved through photolithography machines processing ~100 wafers per hour. This precision ensures defect-free dies, critical for high-yield production.

Photolithography and Etching

Photolithography is the cornerstone of GPU manufacturing, using light to pattern circuits onto silicon wafers. EUV lithography, utilized in 4nm and 5nm nodes, achieves finer resolutions than traditional DUV systems. The process involves:

- Photoresist Application: A light-sensitive material is applied to the wafer.

- Exposure: EUV light (13.5 nm wavelength) patterns the photoresist through a mask.

- Development: Unexposed photoresist is removed, leaving the desired circuit pattern.

- Etching: Plasma or chemical etching transfers the pattern onto the silicon.

Etching precision is critical, as errors can lead to defective transistors. TSMC’s EUV systems maintain alignment within nanometers, ensuring high yields for complex GPU dies like the AD102 (RTX 4090), which contains 76.3 billion transistors.

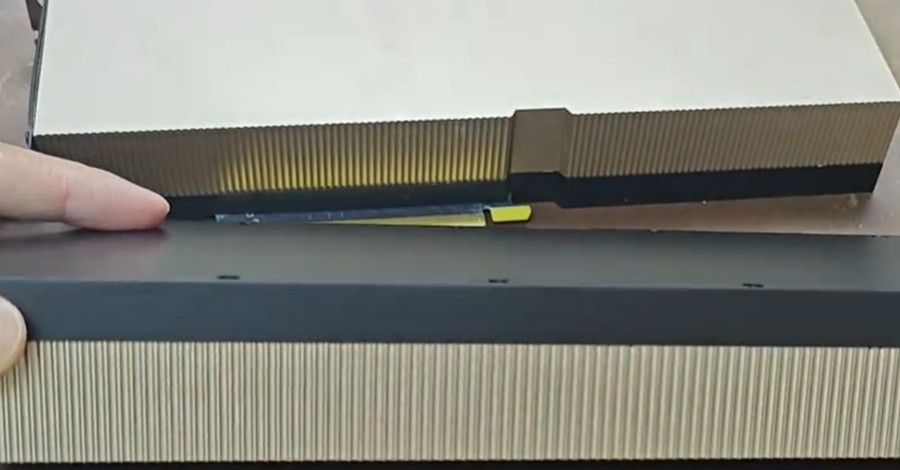

Packaging and Assembly

After die fabrication, GPU chips are packaged and assembled into graphics cards. This process includes:

- Die Bonding: The GPU die is attached to a substrate using precise soldering techniques.

- Wire Bonding: Microscopic wires connect the die to the substrate, requiring sub-micron accuracy.

- Encapsulation: The chip is sealed to protect it from environmental factors.

AIB partners like MSI and ASUS handle final assembly, integrating the GPU with memory modules (e.g., GDDR6X or HBM3), power delivery systems, and cooling solutions. For example, the RTX 4090 uses a 384-bit memory bus with 24 GB GDDR6X, requiring precise placement of memory chips to maintain signal integrity.

Thermal Management and Cooling

High-performance GPUs like the RTX 4090 (450W TDP) and H100 (700W TDP) generate significant heat, necessitating advanced cooling solutions. Manufacturing technologies include:

- Heat Pipes and Vapor Chambers: Copper heat pipes and vapor chambers transfer heat from the GPU die to cooling fins, fabricated with precision milling to ensure tight tolerances.

- Thermal Interface Materials (TIMs): High-conductivity TIMs, such as indium-based compounds, are applied with automated dispensing systems to ensure uniform coverage.

- Fan and Shroud Assembly: Injection-molded shrouds and high-RPM fans are assembled with sub-millimeter precision to optimize airflow.

Quadro and data center GPUs often use liquid cooling or server-grade air cooling, requiring additional manufacturing steps like leak-proof coolant channels.

Testing and Quality Control

Quality control is integral to GPU manufacturing, given the complexity of modern chips. Automated testing systems verify:

- Functional Testing: Ensures CUDA, RT, and Tensor cores operate correctly.

- Thermal Testing: Validates cooling performance under maximum load.

- Electrical Testing: Checks power delivery and signal integrity.

Defect rates are minimized through automated optical inspection (AOI) and X-ray analysis, detecting issues like solder voids or misaligned components. For example, the H100’s HBM3 memory requires rigorous testing to ensure 3 TB/s bandwidth performance.

Manufacturing Considerations

While NVIDIA’s GPUs achieve high performance, manufacturing complexities present challenges. The reliance on TSMC’s foundries introduces supply chain dependencies, with potential delays due to global demand for advanced nodes. Additionally, the high cost of EUV lithography machines (~$150,000 per hour of chip production) increases fabrication expenses, impacting pricing for end consumers. Environmental concerns also arise, as semiconductor manufacturing involves hazardous chemicals like brominated flame retardants (BFRs) and heavy metals, requiring careful waste management to mitigate ecological impact.

Conclusion

NVIDIA’s graphics cards, spanning GeForce, Quadro, A100/H100, and Tegra series, cater to diverse applications, each requiring specialized manufacturing technologies. From TSMC’s 4nm EUV lithography to AIB partners’ precision assembly, the production process demands nanometer-level accuracy and robust quality control. These technologies ensure NVIDIA GPUs meet the performance and reliability needs of gaming, professional visualization, AI, and embedded systems, solidifying NVIDIA’s leadership in the GPU market.

FAQ about NVIDIA Graphics Cards and Their Manufacturing

What are the main categories of NVIDIA graphics cards?

NVIDIA graphics cards are primarily classified into four series, each tailored for specific applications:

GeForce Series: Designed for gaming and consumer use (e.g., RTX 4090, RTX 5090).

Quadro Series: Targeted at professional visualization (e.g., RTX 6000 Ada) for industries like architecture and media production.

A100/H100 Series: Built for data centers, focusing on AI, HPC, and machine learning.

Tegra Series: System-on-chip (SoC) units for embedded systems (e.g., automotive, IoT).

How do GeForce and Quadro GPUs differ?

While both are high-performance GPUs, key differences include:

Target Use Case: GeForce prioritizes gaming with features like ray tracing and DLSS; Quadro focuses on professional software (e.g., Autodesk Maya) with ECC memory for reliability.

Memory: Quadro cards often have larger memory capacities (e.g., 48 GB GDDR6 in RTX 6000 Ada) compared to consumer GeForce models.

Optimizations: Quadro includes certifications for professional applications, ensuring stability in workstation environments.

What makes the A100/H100 series suitable for data centers?

These GPUs are optimized for large-scale computing with:

High-Bandwidth Memory (HBM3): Up to 141 GB HBM3 with 3 TB/s bandwidth (H100) for fast data access.

Advanced Tensor Cores: 528 4th-gen Tensor Cores in the H100, enabling 4 petaFLOPS of FP8 precision for AI workloads.

Thermal and Power Design: Built to handle extreme loads (e.g., 700W TDP for H100) with robust cooling.

What process nodes are used to manufacture NVIDIA GPUs?

NVIDIA partners with TSMC for GPU die fabrication, using advanced process nodes:

4nm (N4): Used in GeForce RTX 4090 and H100, offering high transistor density and efficiency.

5nm (N5): Powers RTX 30 Series and A100, improving performance over 7nm.

7nm (N7): Used in older Turing GPUs (RTX 20 Series), balancing power and performance.