Turning is a fundamental machining process used to create cylindrical parts by removing material from a rotating workpiece using a cutting tool. This subtractive manufacturing technique is widely employed in industries such as automotive, aerospace, and electronics to produce components like shafts, rods, and tubular parts with precise dimensions. This article provides a detailed exploration of turning machining, including its types, tools, techniques, and critical parameters, offering a professional and systematic guide for practitioners and engineers.

Overview of Turning Machining

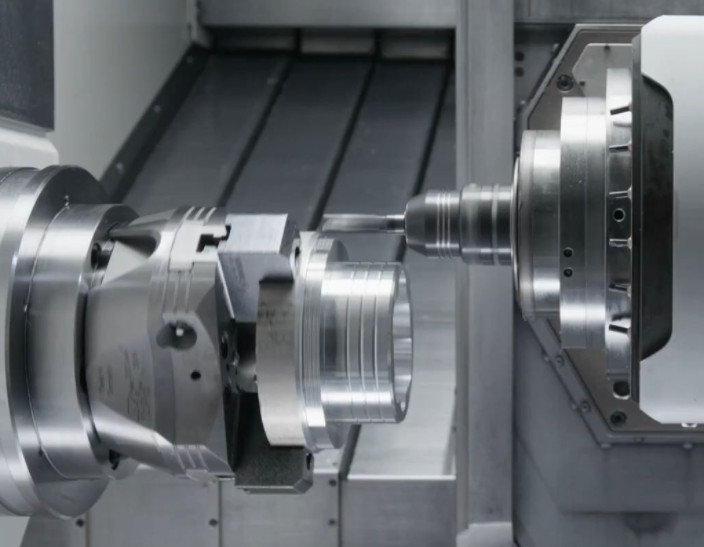

Turning involves rotating a workpiece on a lathe while a stationary cutting tool removes material to achieve the desired shape. The process is typically performed on a lathe, which can be manually operated or controlled via computer numerical control (CNC). Turning is primarily used to create external cylindrical surfaces, but it can also machine internal surfaces (boring) or flat surfaces (facing). The versatility of turning makes it suitable for materials such as metals, plastics, and composites, with applications ranging from simple bolts to complex aerospace components.

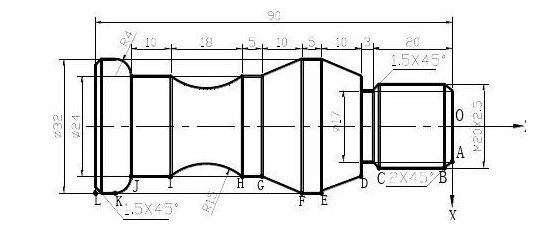

The primary goal of turning is to reduce the workpiece diameter to meet precise specifications, often defined by engineering drawings. The process requires careful consideration of parameters such as cutting speed, feed rate, and depth of cut to ensure accuracy, surface finish, and tool longevity. Turning operations are categorized based on the surface being machined and the specific outcome desired, such as roughing, finishing, or threading.

Types of Turning Operations

Turning encompasses a variety of operations, each designed to achieve specific geometric features or surface characteristics. Below are the primary types of turning operations, each with distinct applications and techniques.

Straight Turning

Straight turning reduces the diameter of a cylindrical workpiece to a uniform dimension. The cutting tool moves parallel to the workpiece’s axis of rotation, removing material evenly. This operation is used for creating shafts, rods, and other components requiring consistent diameters. It can be divided into rough turning, which removes large amounts of material quickly, and finish turning, which achieves precise dimensions and smooth surfaces.

Parameters:

- Cutting Speed: 100–300 m/min for steel, 200–500 m/min for aluminum (depending on tool material).

- Feed Rate: 0.1–0.5 mm/rev for roughing, 0.05–0.2 mm/rev for finishing.

- Depth of Cut: 1–4 mm for roughing, 0.2–1 mm for finishing.

Taper Turning

Taper turning produces conical shapes by gradually reducing the workpiece diameter from one end to the other. The cutting tool is angled relative to the workpiece axis, often using a taper attachment or CNC programming. This operation is critical for components like machine tool spindles and drive shafts, where tapered ends ensure proper fitting.

Parameters:

- Taper Angle: Typically 1°–15°, depending on application.

- Cutting Speed: Similar to straight turning, adjusted for material hardness.

- Feed Rate: 0.05–0.3 mm/rev, depending on taper complexity.

Facing

Facing involves machining the end of a workpiece to produce a flat surface perpendicular to the axis of rotation. The cutting tool moves radially across the workpiece, often as the first or last operation in turning. Facing ensures proper length and prepares surfaces for subsequent machining.

Parameters:

- Cutting Speed: 80–250 m/min for steel, higher for softer materials.

- Feed Rate: 0.05–0.15 mm/rev.

- Depth of Cut: 0.1–0.5 mm for finishing passes.

Grooving

Grooving creates narrow channels or grooves on the external or internal surfaces of a workpiece. It is used for applications like oil grooves, retaining ring grooves, or preparing for parting operations. Grooving tools are typically wider than standard turning tools, and multiple passes may be required for wider grooves.

Parameters:

- Tool Width: 1–5 mm, depending on groove size.

- Feed Rate: 0.05–0.2 mm/rev.

- Depth of Cut: 0.5–2 mm per pass.

Parting

Parting, or cutoff, involves cutting a workpiece from its parent stock to create a separate component. The parting tool, a thin blade, moves perpendicular to the workpiece axis until it reaches the center, causing the part to separate. A part catcher is often used to collect the finished component.

Parameters:

- Cutting Speed: 50–150 m/min, lower due to tool stress.

- Feed Rate: 0.02–0.1 mm/rev.

- Tool Width: 1–3 mm.

Threading

Threading cuts helical grooves (threads) into a workpiece to create fasteners like bolts or nuts. The tool follows a precise path synchronized with the workpiece rotation, often requiring multiple passes to achieve the desired thread depth and pitch.

Parameters:

- Thread Pitch: 0.5–6 mm, depending on thread standard (e.g., ISO, UNC).

- Cutting Speed: 30–100 m/min, lower for harder materials.

- Depth of Cut: 0.05–0.2 mm per pass.

Tools Used in Turning

Turning relies on specialized tools, primarily single-point cutting tools, designed to remove material efficiently while maintaining precision. The choice of tool material, geometry, and coating significantly impacts performance and part quality.

Single-Point Cutting Tools

Single-point cutting tools have one cutting edge and are used for operations like turning, facing, and boring. These tools are typically made from high-speed steel (HSS), carbide, or ceramic materials, with carbide being the most common due to its durability and heat resistance.

Tool Materials:

| Material | Properties | Applications |

|---|---|---|

| High-Speed Steel (HSS) | Good toughness, moderate heat resistance | General-purpose turning, softer materials |

| Carbide | High hardness, excellent heat resistance | High-speed turning, hard materials |

| Ceramic | Extreme hardness, high-temperature resistance | High-speed finishing, heat-resistant alloys |

Tool Geometry

Tool geometry, including rake angle, clearance angle, and nose radius, affects cutting efficiency and surface finish. A positive rake angle reduces cutting forces but may weaken the tool, while a larger nose radius improves surface finish but increases cutting forces.

Typical Geometry Parameters:

- Rake Angle: 5°–15° for metals, 0°–5° for brittle materials.

- Clearance Angle: 5°–10° to prevent tool rubbing.

- Nose Radius: 0.4–1.2 mm for finishing, 0.8–2 mm for roughing.

Tool Holders and Workholding Devices

Tool holders secure the cutting tool in the lathe’s tool post or turret, ensuring stability during machining. Common workholding devices include chucks, collets, and faceplates, which hold the workpiece securely during rotation.

Workholding Options:

- Three-Jaw Chuck: For cylindrical parts, self-centering.

- Collet: For precise gripping of small-diameter parts.

- Faceplate: For irregular or large workpieces.

Techniques in Turning Machining

Turning techniques vary depending on whether the process is manual or CNC-controlled, with each offering distinct advantages in precision, efficiency, and complexity.

Manual Turning

Manual turning is performed on conventional lathes, where the operator controls tool movement and feed rate. This technique is suitable for low-volume production or prototyping but requires skilled operators to achieve consistent results. Manual turning is less precise than CNC turning and demands constant supervision.

CNC Turning

CNC turning uses computer-controlled lathes to automate tool movements and machining parameters. Programs written in G-code or generated via computer-aided manufacturing (CAM) software control the lathe, ensuring high precision and repeatability. CNC turning is ideal for high-volume production and complex geometries, such as contours or intricate threads.

CNC Advantages:

- Precision tolerances as low as ±0.01 mm.

- Ability to machine complex shapes with multi-axis control.</li Consideration: CNC systems are more expensive.

- Reduced operator fatigue for long production runs.

Hard Turning

Hard turning involves machining hardened materials (e.g., steel with hardness >45 HRC) using advanced tools like ceramic or cubic boron nitride (CBN) inserts. This technique eliminates the need for grinding in some applications, reducing production time.

Parameters:

- Cutting Speed: 50–150 m/min.

- Feed Rate: 0.05–0.2 mm/rev.

- Depth of Cut: 0.1–0.5 mm.

Key Parameters in Turning

The success of turning operations depends on optimizing key parameters, which influence tool life, surface finish, and dimensional accuracy.

| Parameter | Description | Typical Range |

|---|---|---|

| Cutting Speed | Speed of the workpiece surface relative to the tool (m/min). | 50–500 m/min, depending on material. |

| Feed Rate | Distance the tool advances per revolution (mm/rev). | 0.05–0.5 mm/rev. |

| Depth of Cut | Thickness of material removed per pass (mm). | 0.1–4 mm. |

Considerations in Turning Machining

Several practical considerations ensure optimal turning performance:

- Tool Wear: High cutting speeds and hard materials accelerate tool wear, requiring frequent tool changes.

- Workpiece Material: Material properties, such as hardness and ductility, affect tool selection and cutting parameters.

- Surface Finish: Smaller nose radii and lower feed rates improve surface finish but may increase machining time.

- Safety: Flying chips and rotating parts pose risks, necessitating protective equipment and proper machine guarding.

Conclusion

Turning machining is a cornerstone of precision manufacturing, offering unmatched versatility for creating cylindrical components. By understanding the various types of turning operations, tools, techniques, and parameters, manufacturers can achieve high-quality results tailored to specific applications. Whether using manual or CNC lathes, optimizing cutting speed, feed rate, and depth of cut is critical to balancing efficiency, precision, and tool life. This guide provides a foundation for professionals seeking to master turning machining and deliver reliable, high-performance components.