Our Blog

Latest articles

Guide to Surface Treatment Processes

Comprehensive guide to surface treatment processes, including screen printing, pad printing, etching, and more, with detailed technical explanations.

Swiss Machining: Guide, Uses, and Difficulties

A comprehensive guide to Swiss machining, detailing its uses, technical parameters, and operational difficulties.

Eight Major Metal Forming Processes Explained

Explore the eight major metal forming processes, including casting, plastic forming, machining, welding, powder metallurgy, metal injection molding, semi-solid forming, and 3D printing, with detailed

Copper: Guide, Applications, and Machining

Comprehensive guide on copper, its applications, and CNC machining processes, focusing on material properties, precision, complexity, and machining difficulties.

Brass: Guide, Applications, and Precision Machining

Comprehensive guide on brass, its applications, and CNC machining processes, focusing on precision, complexity, and material properties for manufacturing.

Aluminum vs Stainless Steel

Comprehensive comparison of aluminum vs stainless steel, detailing properties, applications, and technical parameters for informed material selection.

Deep Groove Rim Forging: Process and Techniques

Detailed analysis of deep groove rim forging process, materials, and equipment for automotive wheel hub manufacturing.

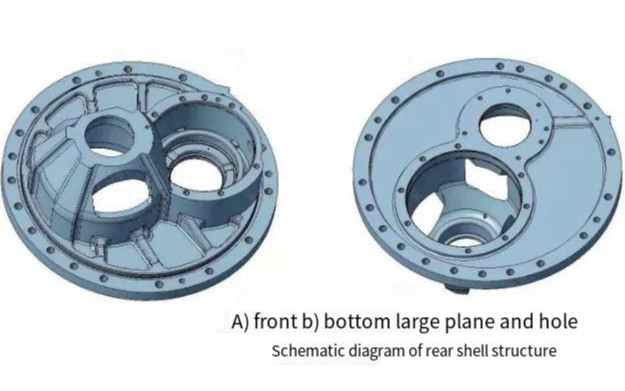

Process Analysis for Machining Box-Type Parts

Detailed process analysis for machining box-type parts, covering workpiece features, equipment, tooling, tool selection, and clamping methods.

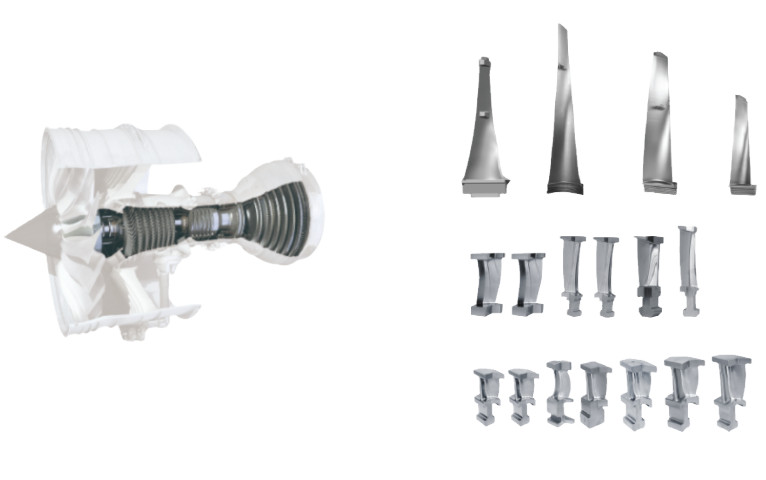

Turbine Blades: Guide, Applications, and Machining

Comprehensive guide on turbine blades, covering applications, machining processes, materials, and precision requirements.

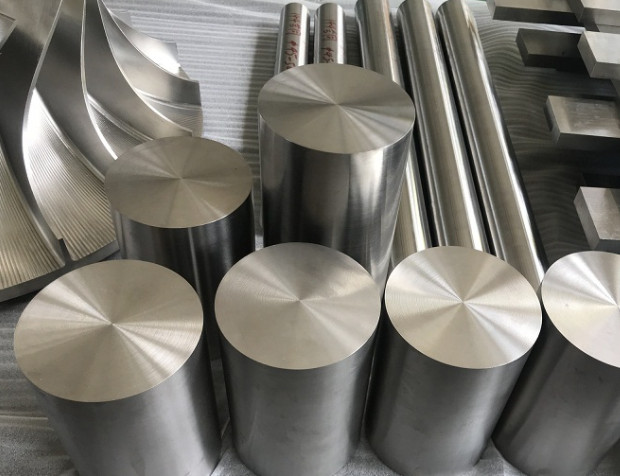

Titanium Machining: Guide, Types, and Difficulties

Comprehensive guide to titanium machining, covering types, difficulties, materials, prototyping, precision, and complexity with detailed technical insights.

Controlling Deformation in Aluminum Alloy Square Frame Machining

Detailed process for controlling deformation in aluminum alloy square frames, focusing on precision machining techniques and tooling solutions.

Enhancing Machining Accuracy for Vertical Stabilizer Processing

Learn how to improve machining accuracy of specialized machine tools for vertical stabilizer processing with automated control systems.

Efficient Batch Processing of Small Positioning Blocks

Efficient and cost-effective batch processing method for small positioning blocks using combined arrangement and wire cutting to improve quality and productivity.

Key-Locked Thread Inserts: Processing and Application

Detailed analysis of key-locked thread inserts, focusing on processing, installation, and maintenance for aluminum-magnesium alloy applications.

China's CNC Companies: Guide, Types and Advantages

Comprehensive guide to China's CNC companies, detailing types of CNC machines, their applications, and key advantages for global industries.

Manufacturing Techniques for Centrifugal Pump Model Impellers

Detailed analysis of manufacturing techniques for centrifugal pump model impellers, covering split, integral, special processing, and 3D printing methods.

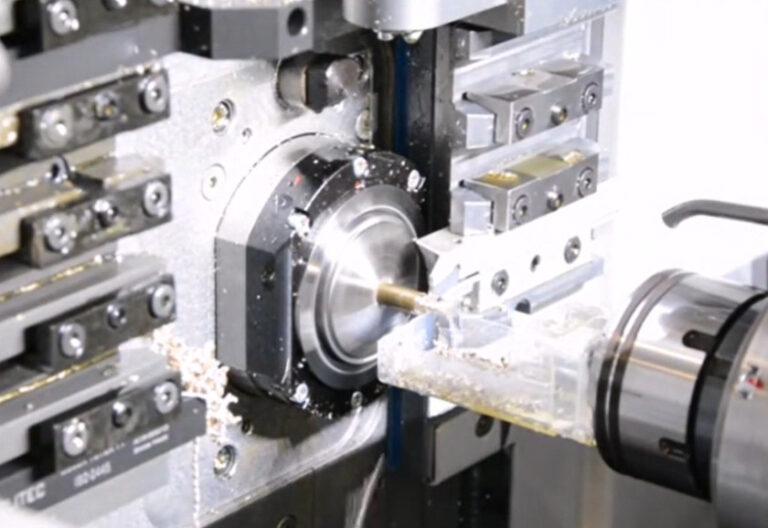

Precision Curved Gear Machining

Comprehensive guide on precision curved gear machining using JDSoft SurfMill software, detailing CAM programming, tool selection, and in-machine measurement for high-accuracy gear production.

Five-Axis CNC Machining of Irregular Human Bone Models

Detailed process of machining irregular human bone models using five-axis CNC, including modeling, toolpath generation, and verification.

Aluminum Machining: Guide, Types, and Difficulties

Comprehensive guide to aluminum machining, covering types, techniques, material properties, and difficulties including precision and complexity.

Why Cold Forging Requires Pretreatment: Analysis and Solutions

Analysis of cold forging pretreatment, normalization issues, and preventive measures for 16MnCr5 steel components.

Stainless Steel Machining: Guide, Types, and Difficulties

Comprehensive guide to stainless steel machining, covering types, material properties, difficulties, and precision parameters for optimal results.

Optimized Machining of Inclined Cylindrical Bosses

Optimized machining process for inclined cylindrical bosses using macro programming and layered contour fitting for high efficiency and quality.

Centrifugal Impeller Failure Analysis in Aero-Engine

Analysis of centrifugal impeller hub failure due to high-cycle fatigue and corrosion in an aero-engine, including detailed fractographic and metallographic examinations.

Reliability Analysis of Aviation Solenoid Valve Repair

Analysis of material reduction repair for a damaged threaded joint in an aviation fuel solenoid valve using theoretical and finite element methods to ensure reliability.