Injection mold toolmaking is a cornerstone of plastic injection molding, enabling the production of precise plastic components for industries such as automotive, medical, electronics, and consumer goods. This process involves designing, manufacturing, maintaining, and repairing molds that shape molten plastic into functional parts under high pressures and temperatures. Toolmakers integrate advanced equipment, materials science, and engineering expertise to create molds that meet stringent quality and performance standards. In regions like Brisbane, Australia, and global manufacturing hubs such as China and Malaysia, toolmaking operations combine local and international capabilities to deliver versatile solutions. This guide explores the intricacies of injection mold toolmaking, covering mold design, manufacturing processes, maintenance practices, and repair techniques. Detailed parameters, industry applications, and technical insights provide a thorough understanding of this essential manufacturing discipline.

Fundamentals of Injection Mold Toolmaking

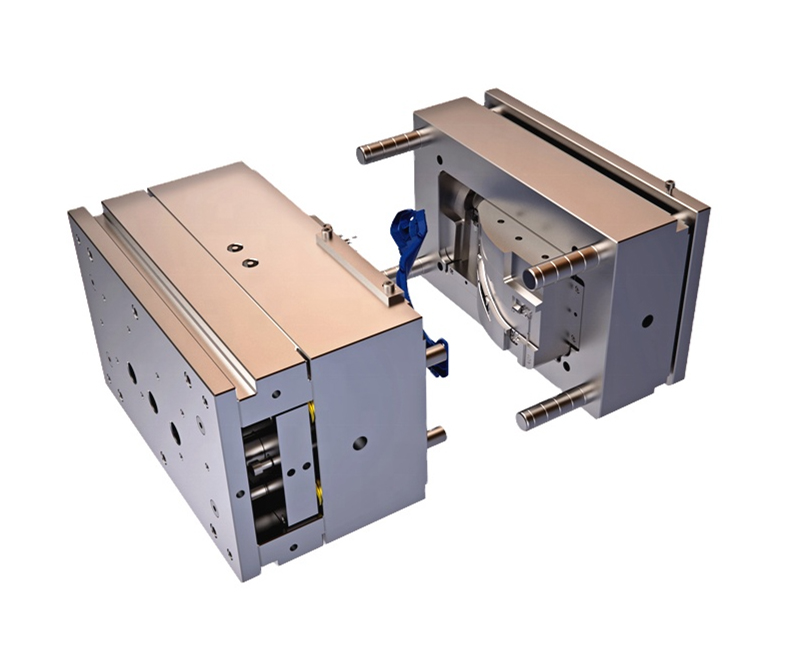

Injection mold toolmaking involves creating precision molds for injection molding machines to produce plastic parts with tolerances as tight as ±0.05 mm. These molds, typically made from high-grade steel or aluminum, withstand pressures of 1000–2000 bar, temperatures of 200–300°C, and cycle counts ranging from 10,000 to 1,000,000. The process begins after finalizing a product design, translating CAD models into molds that ensure consistent part quality and production efficiency. Toolmakers collaborate with designers and manufacturers to optimize molds for manufacturability, cost, and performance, ensuring cycle times of 20–60 seconds.

Mold Design Process

Mold design is critical to toolmaking, requiring expertise in part geometry, material properties, and production requirements. Key design considerations include:

- Draft Angles: Angles of 1–3 degrees facilitate part ejection, reducing mold wear.

- Wall Thickness: Uniform thicknesses of 1.5–3 mm minimize defects like sink marks.

- Gate Placement: Strategic locations optimize material flow, reducing cycle times by 10–20%.

- Cooling Channels: Conformal channels, with diameters of 6–12 mm, enhance heat dissipation, shortening cycle times by 30%.

Design software like SolidWorks or Moldflow simulates mold filling, cooling, and warpage, ensuring surface finishes of Ra 0.8–1.6 μm.

Mold Materials

Molds are crafted from materials chosen for durability, machinability, and thermal properties:

- P20 Steel: A pre-hardened steel with a yield strength of 800 MPa, used for molds with 50,000–100,000 cycles.

- H13 Steel: A hot-work steel with a hardness of 45–50 HRC, suitable for 1,000,000+ cycles.

- Aluminum 7075: With a tensile strength of 570 MPa, used for prototype molds with 5,000–10,000 cycles.

- Stainless Steel 420: Corrosion-resistant, with a hardness of 50–52 HRC, for medical applications.

Toolmaking Equipment

Advanced equipment ensures precision in toolmaking:

- CNC Machining Centers: 3-, 4-, and 5-axis machines achieve tolerances of ±0.005 mm.

- Electrical Discharge Machining (EDM): Wire and sinker EDM create features with accuracies of ±0.002 mm.

- High-Speed Milling: Spindle speeds of 20,000–40,000 RPM ensure finishes of Ra 0.4 μm.

- Coordinate Measuring Machines (CMM): Verify dimensions with accuracies of ±0.001 mm.

These tools enable mold production with lead times of 5–14 days for prototypes and 4–8 weeks for production molds.

Mold Manufacturing Process

Mold manufacturing involves precise steps to transform designs into functional molds, supporting industries with diverse production needs.

Design Validation

Mold designs are validated using simulation software to predict material flow, cooling, and defects. Moldflow analysis ensures tolerances of ±0.05 mm by identifying issues like warpage. Design for Manufacturability (DFM) feedback optimizes gate sizes (0.5–2 mm) and runner systems, reducing waste by 10–15%.

Machining and Fabrication

Cavities, cores, and ejector pins are machined using CNC and EDM equipment. High-speed milling achieves finishes of Ra 0.4–0.8 μm, while EDM creates geometries with corner radii of 0.1 mm. Polishing to SPI standards (e.g., A-1, C-1) ensures part release and aesthetics.

Mold Assembly

Molds are assembled with components like slides and cooling systems, maintaining cavity-to-core gaps of 0.01–0.02 mm. Testing on injection machines with clamping forces of 50–500 tons verifies performance under pressures of 1000–1500 bar.

Testing and Validation

Trial runs produce sample parts, inspected for accuracy (±0.05 mm) and finish (Ra 1.6 μm). First Article Inspection (FAI) reports confirm compliance. Adjustments to gates or cooling channels optimize cycle times (20–60 seconds).

Mold Maintenance and Repair

Maintenance and repairs extend mold lifespans and ensure consistent production, addressing wear and performance issues.

Preventive Maintenance

Preventive maintenance includes:

- Disassembly and Cleaning: Using ultrasonic cleaners every 5,000–10,000 cycles.

- Blade Replacement: Replacing ejector pins to maintain tolerances of ±0.02 mm.

- Lubrication: High-temperature greases reduce friction by 20–30%.

- Inspection: CMM detects wear within ±0.01 mm.

Records track performance, scheduling maintenance based on cycles or schedules.

Corrective Repairs

Repairs address flash, sink marks, or damage:

- Welding: TIG welding repairs cracks with P20 or H13 fillers.

- Polishing: Restores finishes to Ra 0.8 μm.

- Component Replacement: Replaces pins with lead times of 1–3 days.

Repairs extend lifespans by 20–50%.

Tool Readiness

Molds are prepared for runs of 500–100,000 parts, with test shots verifying injection pressure (800–1200 bar) and quality.

Applications of Injection Mold Toolmaking

Toolmaking supports industries requiring high-precision parts with repeatability.

Automotive

Automotive molds produce dashboards, bumpers, and connectors with tolerances of ±0.05 mm and cycle times of 30–60 seconds. ABS and polycarbonate ensure durability, with molds lasting 100,000 cycles.

Medical

Medical molds create syringes and housings using PEEK, with finishes of Ra 0.8 μm and tolerances of ±0.02 mm. Stainless steel molds ensure sterility.

Electronics

Electronics molds produce enclosures and keypads with snap-fits, using nylon and PC, supporting runs of 10,000–50,000 parts and tolerances of ±0.05 mm.

Continuous Improvement in Toolmaking

Toolmakers enhance quality, reduce costs, and improve efficiency through continuous improvement.

Design Optimization

Recommendations adjust wall thickness to 1.5–2 mm, reducing material use by 5–10%, and optimize gates to minimize weld lines.

Equipment Upgrades

High-speed CNC and EDM systems reduce machining times by 20–30% and improve tolerances to ±0.002 mm.

Process Enhancements

Automated inspection with laser scanners detects defects within ±0.001 mm. Lean practices reduce lead times by 10–15%.

Global and Local Toolmaking Operations

Toolmaking combines local expertise with global partnerships for versatile solutions.

Local Operations

Brisbane facilities offer rapid mold design and repair, with maintenance lead times of 1–7 days. In-house equipment and engineers provide DFM feedback.

International Partnerships

Partnerships in China and Malaysia offer cost savings of 20–30% for high-volume molds. North American partners ensure compliance with specialized standards, like FDA regulations.

FAQ: Injection Mold Toolmaking

What is injection mold toolmaking?

Injection mold toolmaking involves designing, manufacturing, maintaining, and repairing molds for plastic injection molding, producing parts with tolerances of ±0.05 mm for automotive and medical industries.

What materials are used for injection molds?

Mold materials include P20 steel (800 MPa, 50,000–100,000 cycles), H13 steel (45–50 HRC, 1,000,000+ cycles), aluminum 7075 (570 MPa, 5,000–10,000 cycles), and stainless steel 420 (50–52 HRC).

How long does it take to manufacture an injection mold?

Prototype molds take 5–14 days, while production molds require 4–8 weeks, depending on complexity and material.

What maintenance is required for injection molds?

Preventive maintenance includes cleaning, blade replacement, and lubrication every 5,000–10,000 cycles. Repairs like welding or polishing restore finishes to Ra 0.8 μm.

Injection mold toolmaking is integral to plastic injection molding, enabling high-quality part production with precision and efficiency. Through advanced design, manufacturing, maintenance, and repair processes, toolmakers support industries from automotive to medical. Local and global operations enhance scalability, while continuous improvement drives innovation and reliability in manufacturing workflows.